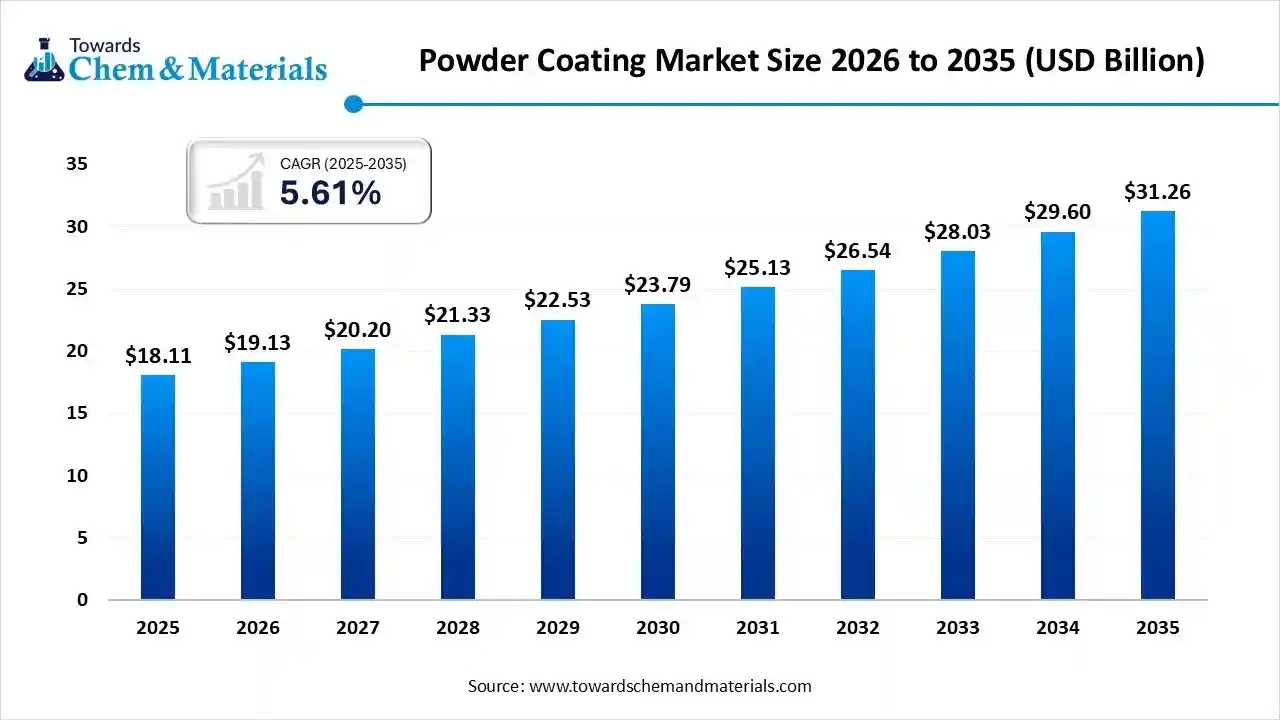

Ottawa, Feb. 18, 2026 (GLOBE NEWSWIRE) -- The global Powder Coatings market size was estimated at USD 18.11 billion in 2025 and is expected to increase from USD 19.13 billion in 2026 to USD 31.26 billion by 2035, growing at a CAGR of 5.61% from 2026 to 2035. Asia Pacific dominated the powder coatings market with the largest revenue share of 41.26% in 2025. A global shift towards sustainability, rapid urbanization, material innovation, and rising demand for electrification and consumer goods drive the market. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5513

What is the Significance of Powder Coatings?

The powder coatings market is a growing global industry driven by a shift towards eco-friendly finishes, especially with the rise of electric vehicles and eco-conscious consumers. The manufacturers focus on sustainability and automation by integrating smart manufacturing, alongside innovations such as bio-based renewable resins and UV-curable resins for protecting heat-sensitive substrates, accelerating growth. Additionally, rapid urbanization and zero-emission commitments are driving the expansion.

Powder Coatings Market Report Highlights

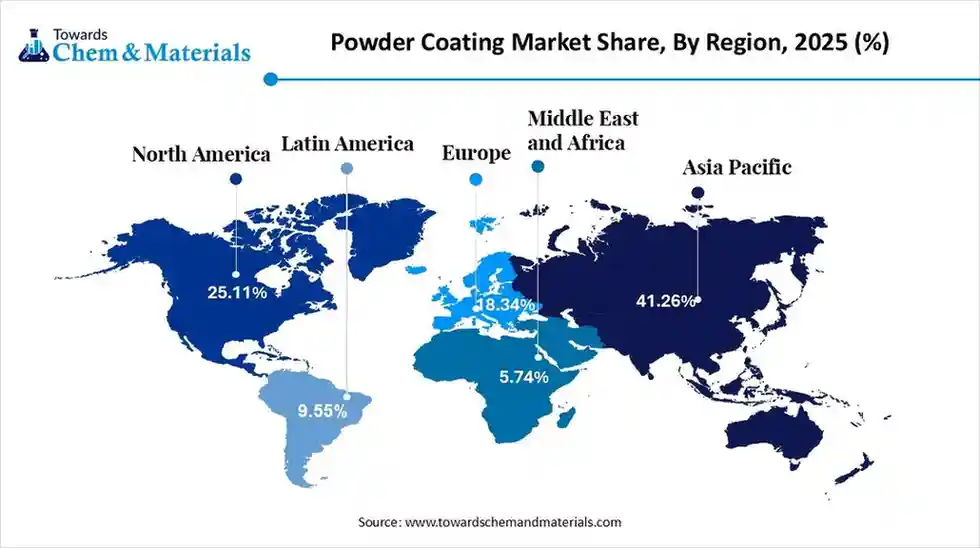

- The Asia Pacific region led the powder coatings market with the revenue share of 41.26% in 2025

- The Europe powder coatings market has captured revenue share of 30.55% in 2024.

- By resin, the polyester segment dominated the market and accounted for the largest revenue share of 28.11% in 2025.

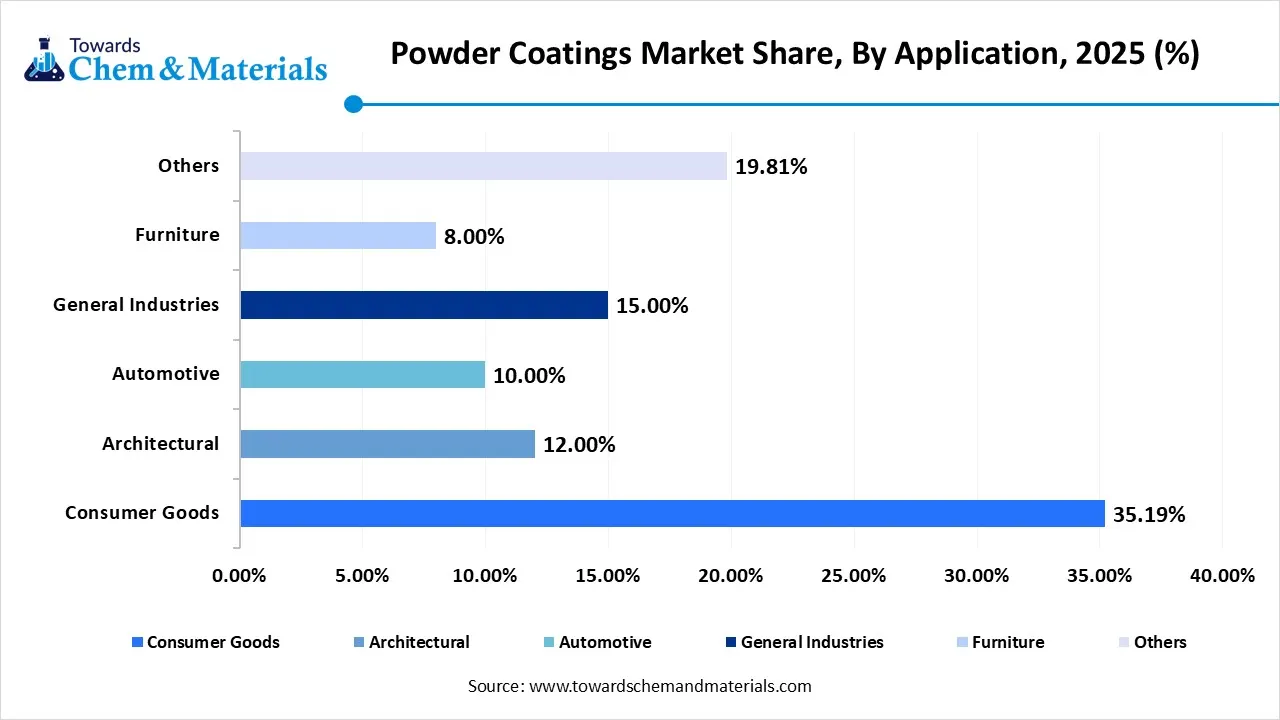

- By application, the consumer goods segment led the market with the largest revenue share of 35.19% in 2025.

Private Industry Investments for Powder Coatings:

- PPG’s $300 Million North American Expansion: PPG is investing $300 million through 2028 to modernize its manufacturing footprint, including a new 250,000-square-foot facility in Tennessee to support the automotive and industrial sectors.

- AkzoNobel’s $30 Million North American Upgrade: AkzoNobel allocated $30 million in 2024 to enhance its U.S. plants with advanced manufacturing technologies to improve production efficiency and sustainability.

- Sherwin-Williams’ Pune Facility Investment: Sherwin-Williams recently established a dedicated powder coatings plant in India to capitalize on high demand within the South Asian infrastructure and industrial markets.

- AkzoNobel’s €21 Million Italian Expansion: The company added four new production lines at its site in Como, Italy, specifically targeting the premium architectural and automotive primer segments.

- AkzoNobel’s €18.5 Million Vietnam Investment: This multi-site expansion in Vietnam added five production lines to serve the rapidly growing consumer electronics and home appliance industries in Southeast Asia.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

What Are Major Trends in the Powder Coatings Market?

- Shift Towards High-Performance Material Innovation: The industry is focused on innovation of ultra-low-temperature curing chemistries and UV-curable resins. Its ability to apply high-performance powder finishes to advanced plastics, carbon-fiber composites, and especially heat-sensitive substrates.

- Focus on Sustainability and Decarbonization: The manufacturers' focus on commitments to the circular economy that promote the adoption of bio-based renewable resins aligns industrial production with the global push for renewable resource management and carbon neutrality goals.

- Surge for Electric Vehicle and Dielectric Revolution: The global automotive shift is reshaping the market by offering zero-VOC and fire-retardant materials for battery enclosures, ensuring safety and longevity for next-generation EVs.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5513

Powder Coatings Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 19.13 billion |

| Revenue forecast in 2035 | USD 31.26 billion |

| Growth rate | CAGR of 5.61% from 2026 to 2035 |

| Base year for estimation | 2025 |

| Historical data | 2018 - 2025 |

| Forecast period | 2026 - 2035 |

| Quantitative units | Volume in Kilotons, Revenue in USD million and CAGR from 2026 to 2035 |

| Report coverage | Revenue & volume forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments covered | Resin, application, region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Country scope | U.S.; Canada; Mexico; Germany; UK; France; Italy; Spain; Russia; Benelux; Turkey; Switzerland; Sweden; Poland; Austria; Norway; Denmark; Finland; Portugal; Czech Republic; Slovenia; China; Japan; India; South Korea; Thailand; Australia; Brazil; Argentina; Saudi Arabia; South Africa |

| Key companies profiled | Akzo Nobel N.V.; The Sherwin-Williams Company; PPG Industries, Inc.; BASF SE; Arkema; JOTUN; Nippon Paint Holdings Co., Ltd.; RPM International, Inc. |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Raw materials for powder coatings

The main raw material components used in powder coating formulations include:

Resins

Resins are the key component of powder coatings. The range of resins used is increasing steadily in an attempt to meet the more demanding needs of new market sectors. This component in the formulation will largely determine the processing and end-use performance properties of powder coatings. There are two main classifications for powder coatings: thermoplastic and thermoset. The final coating has a different chemical structure than the applied powder.

Thermoplastics powders

A thermoplastic powder coating melts and flows when heat is applied but continues to have the same chemical composition once it cools to a solid coating. They are typically high molecular weight materials that require high temperatures to melt and flow. The primary advantage of thermoplastic powder coatings is that they form a smoother finish and require less energy. They are commonly applied by fluidized bed application, and the parts are both preheated and post-heated. Most of the thermoplastic powder coatings have marginal adhesion so that the substrate must be pretreated and sometimes primed prior to coating application.

The common examples of thermoplastic powder coatings are given below.

- Polyvinyl chloride (PVC)

PVC coatings find use in FDA-approved applications such as frozen food shelving and dishwasher baskets. Other uses include general-purpose electrical insulation, chain link fence wire, and outdoor furniture. Key features of PVC coatings include:

- Softness, glossy surface & flexibility

- Impact strength & resilience

- Salt spray & weathering resistance

- Chemical & water resistance

Special primers are generally required for optimal adhesion. Two types of vinyl powder are used: dry blends and melt mixed. The dry blends are less expensive, but the melt mixed materials are superior in performance.

- Polyolefin

Polyethylene and polypropylene powder coatings provide soft and waxy films that have characteristics very similar to their plastic counterparts. Polyolefin powder coatings are used primarily for their low cost and ease of application. However, certain properties make them attractive in many applications including:

- Toughness

- Low water absorption

- Excellent detergent and chemical resistance

- Good electrical insulation characteristics

- High durability, and

- Some solvents can break them down quickly

Polyolefins are often used to coat laboratory equipment because the surface is easily cleaned. They are also used for food handling equipment and for automotive applications such as battery hold-downs.

- Nylon

Nylon powders are practically all based nylon 11. Nylon 6/10 is sometimes used but at high cost. Nylon powders are used to produce powder coatings which of a wide range of benefits, including:

- Toughness

- Excellent abrasion, wear, and impact resistance

- A low coefficient of friction

- Good chemical and solvent resistance

- Smooth surface finish

Generally, a primer must be used with nylon powder coatings to achieve the adhesion level needed for higher performance applications. Nylons can be formulated for food contact applications, outdoor applications such as light fixtures or seating and marine applications where they completely encapsulate fittings, bolts, and other hardware items.

- Polyester

Thermoplastic polyester powder materials have better than average adhesion properties without the need for a primer. They also exhibit good UV resistance and weatherability. Polyester powder coatings are somewhat more difficult to apply than nylon materials and are not as resistant to abrasion or solvent.

Polyester coatings are often applied to such items as outdoor metal furniture due to their good weatherability, corrosion resistance, and general durability.

- Polyvinylidene fluoride

Polyvinylidiene fluoride (PVF) based coating resins have excellent weathering characteristics and excellent resistance to chemicals exception for certain hydrocarbon solvents. They are used to coat piping and valves used in the chemical process industries. Usually a chromate primer is recommended.

Powder Coatings Market Dynamics

Driver

Green Infrastructure Expansion and Rapid Urbanization

The rising population drives the global investment in sustainable architecture with demand for weather-resistant finishes and ultra-durable materials. The powder coatings offer a corrosion-proof shield for curtain walls, aluminium extrusion and steel frameworks by maintaining structural integrity and colour retention by lowering environmental impact.

Restraints

The Intensive Capital Expenditure and Longer Lead Times

The primary restraint is intensive initial capital expenditure for specialized electrostatic spray and curing oven, that contain higher cost, limiting the adoption, while the powder requires inventory management due to the trouble of colour matching, leading to longer lead time for high-finishes.

Opportunity

Rise of Smart City Infrastructure and Consumer Goods

The transformation of ultra-low bake and UV-curable chemistries unlocked the expansion that leads new revolutionary opportunity in powder technology into consumer electronics, luxury furniture, and aerospace. Additionally, the rise in green building certification enables massive opportunities for high-performance, solar-reflective, and anti-microbial coatings that promote urban energy efficiency and public health.

Empowering Powder Coatings Innovation with the Precision of AI.

This market is experiencing a technological transformation with AI and chemical engineering advancing finishing processes into precise digital science. AI-driven robotic systems with sensors improve transfer efficiency and reduce waste. The digital Twin technology to optimize application and curing in computer-generated environments. Innovations in UV-curable and low-bake resins allow the protection of heat-sensitive materials, setting new standards for sustainable and high-performance coatings.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5513

Powder Coatings Market Segmentation Insights

Resin Insights

Why did the polyester Segment Dominated in the Powder Coatings Market?

Polyester resin dominates the market, serving as a high-performance infrastructure that combines molecular invincibility and surface originality. Its ability to resist UV rays, corrosion, high-velocity impacts, thermal expansion, and its superlative mechanical elasticity boost its demand. Overall, it creates a durable and chemically stable barrier that preserves the substrate's permanence and appearance with a zero-emission fortress.

Powder Coatings Market Share, By Resin, 2025 (%)

| By Resin | Revenue Share, 2025 (%) | |

| Epoxy | 25.00 | % |

| Polyester | 28.11 | % |

| Epoxy-Polyester (Hybrid) | 15.00 | % |

| Acrylic | 10.00 | % |

| Polyurethane | 8.00 | % |

| Others | 13.89 | % |

The epoxy segment is experiencing the fastest growth in the market during the projected period. The material offers impenetrable protection and mechanical strength. Its molecular cross- linking creates a chemically inert shield against harmful fuels, solvents, and salt-saturated environments. It is ideal for heavy-duty application includes pipelines, automotive parts, and machinery, ensuring durability under intense stress and preventing corrosion. Additionally, epoxy neutralizes oxidation at metal substrates and provides structural toughness.

Application Insights

How did the Consumer Goods Segment hold the Largest Share of the Powder Coatings Market?

Powder Coatings Market Share, By Application, 2025 (%)

| By Application | Revenue Share, 2025 (%) | |

| Consumer Goods | 35.19 | % |

| Architectural | 12.00 | % |

| Automotive | 10.00 | % |

| General Industries | 15.00 | % |

| Furniture | 8.00 | % |

| Others | 19.81 | % |

The consumer goods segment is a powerhouse of the market. The rising demand for eco-friendly, solvent-free coatings for appliances and electronics to meet zero-emission targets aligns with modern living. It offers superior mechanical toughness, impact-resistant and chemically durable finishes that resist chemical wear and environmental stress, ensuring products stay pristine. The powder coating ability to provide a vibrant shield against anti-microbial protection and excellent surface finish, driving its versatility in consumer products.

The automotive segment is an emerging segment projected to grow at a CAGR between 2026 and 2035. The industry is shifting towards a clean-energy revolution and high-performance powder coating technology to withstand impacts, corrosion from chemical de-icers, and thermal cycles of high-performance engines. As the industry shifts toward electric and lightweight vehicles, powders provide a high-definition luster, durable, corrosion-proof vault and aesthetic finish, ensuring vehicles remain resilient and visually appealing throughout their lifespan.

Regional Insights

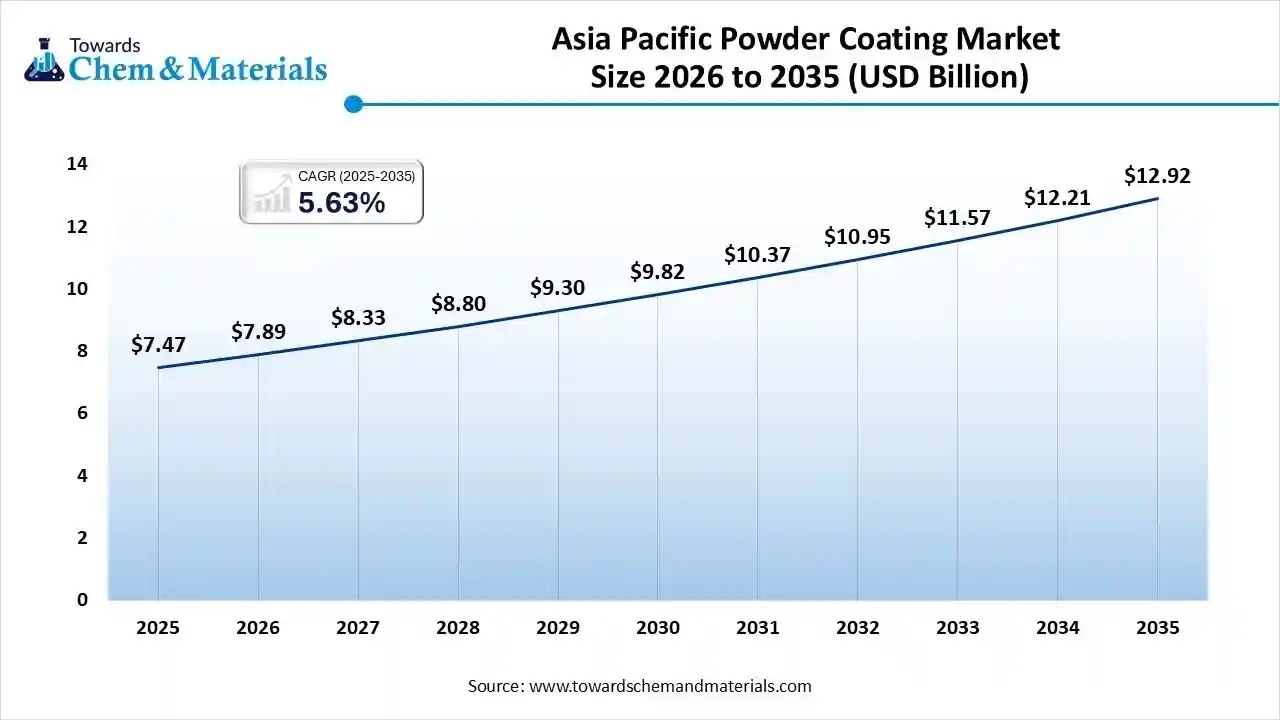

The Asia Pacific powder coatings market size is valued at USD 7.47 billion in 2025 and is expected to reach USD 12.92 billion by 2035, growing at a CAGR of 5.63% from 2026 to 2035. Asia Pacific dominated the powder coatings market share 41.26% in 2025.

The Asia Pacific market leads globally, driven by industrial growth and the transition to sustainable practices by their economic infrastructure. The stringent environmental regulations push industries from liquid paints to zero- emission options, promoting their demand in automotive, electric vehicles, and infrastructure sectors that need durable, corrosion-resistant finishes. The region is a hub for innovation, with substantial investments in low- temperature curing and automation to meet high demand from industrial appliances and consumer goods.

India Powder Coatings Market Trends

India's market is witnessing steady growth, driven by expanding demand from automotive, appliances, architecture, and general industrial sectors. Increasing urbanization and infrastructure development are boosting the use of powder coatings in construction applications such as aluminum extrusions, window frames, and metal furniture.

Why is North America the Fastest-Growing Region in the Powder Coatings Industry?

North America's market growth is driven by its technological precision that emphasises ecological integrity and advanced technology, transforming industrial finishing with eco- friendly resins that eliminate emissions while providing tough surfaces. The rising focus on aerospace, automotive, and infrastructure sectors requires improvement and long-term protection, fueling the regional expansion. North America's shift towards a circular economy with long-lasting, zero-waste finishes, setting quality low-bake efficiencies and resilience standards globally in industrial modernization.

Powder Coatings Market Share,By Region, 2025 (%)

| By Region | Revenue Share, 2025 (%) | |

| North America | 25.11 | % |

| Europe | 18.34 | % |

| Asia Pacific | 41.26 | % |

| Latin America | 9.55 | % |

| Middle East & Africa | 5.74 | % |

U.S. Powder Coatings Market Trends

The U.S. market is experiencing stable growth, supported by strong demand from automotive, construction, appliances, and general industrial sectors. Increasing emphasis on environmentally friendly coatings is accelerating adoption, as powder coatings contain little to no volatile organic compounds (VOCs) and offer high material utilization rates.

More Insights in Towards Chemical and Materials:

- Automotive OEM Coatings Market Size to Reach USD 25.25 Billion by 2034

- Paints and Coatings Market Size to Hit USD 348.04 Bn by 2034

- Biopolymer Coatings Market Size to Reach USD 109.08 Bn by 2035

- Industrial Coatings Market Size to Hit USD 176.06 Bn by 2035

- Automotive Paints & Coatings Market Size to Hit USD 48.22 Bn by 2035

- Liquid Paints & Coatings Market Size to Surge USD 246.39 Bn by 2035

- Waterborne Coatings Market Size to Surpass USD 166.38 Bn by 2035

- Thermal Spray Coatings Market Size to Hit USD 24.82 Billion by 2035

- Stainless Steel Powder Market Size to Hit USD 1,432.39 Mn by 2035

- Aluminum Metal Powder Market Size to Hit USD 4.15 Billion by 2035

- Additive Manufacturing With Metal Powders Market Size to Surpass USD 166.41 Bn by 2035

- Magnesium Powder Market Size to Hit USD 667.14 Million by 2035

- U.S. Powder Coatings Market Size to Hit USD 11.65 Billion by 2034

- Self-Healing Coatings Market Current Status and Future Innovations

- Nanocoatings Market Size to Reach USD 92.17 billion by 2035

- Pipe Coatings Market Size to Hit USD 17.75 Billion by 2035

- Flat Glass Coatings Market Size to Hit USD 16.86 Billion by 2035

- Concrete Floor Coatings Market Size to Surpass USD 8.99 Billion by 2035

- Green Coatings Market Size to Surpass USD 145.19 Billion by 2035

- Wood Coatings Market Size to Worth Around USD 20.36 Bn by 2034

- Functional Coatings Market Volume to Hit 13.14 Million Tons by 2034

- Low-VOC Coatings Market Size to Reach USD 15.16 Billion by 2034

- U.S. Paints & Coatings Market Size to Reach USD 50.23 Billion by 2034

- Sustained Release Coatings Market Size to Hit USD 1,373.63 Mn by 2034

- U.S. Industrial Coatings Market Size to Hit USD 38.81 Bn by 2034

- European Paints & Coatings Market Size to Hit USD 54.27 Bn by 2034

- U.S. Mirror Coatings Market Size to Surge USD 304.83 Million by 2034

- U.S. Powder Coatings Market Size to Hit USD 11.65 Billion by 2034

- U.S. Conformal Coatings Market Size to Surge USD 3.16 Billion by 2034

Power Powder Coatings with Evonik’s High-Performance Solutions

Powder coatings are shaping the future of sustainable finishing - zero VOCs, exceptional durability, and limitless design flexibility. In a market where performance and environmental responsibility define success, Evonik delivers advanced chemistries that help you create coatings that flow perfectly, cure efficiently, and offer long-lasting protection. Because every surface deserves excellence.

Why Choose Evonik for Powder Coatings?

Why Choose Evonik for Powder Coatings?

- Proven Performance: Leading brands like VESTAGON®, TEGO®, ACEMATT®, AEROSIL®, AEROXIDE®, SPHERILEX®, Dynasylan®, and VPS are trusted for ensuring smooth application, controlled gloss, and exceptional adhesion.

- Sustainability at the Core: Powder coatings eliminate solvents and cut emissions. Evonik's additives and crosslinkers make compliance with environmental standards easier than ever.

- Tailored Solutions: From automotive rims to architectural façades, our portfolio adapts to your unique design and performance challenges.

Solutions by Application

Solutions by Application

Automotive & Transportation

- VESTAGON® – Polyurethane crosslinkers for durable, light-stable and weather resistant powder coating systems.

- TEGO® – Additives for flow, leveling, and surface control to achieve flawless finishes.

- ACEMATT® – Silica matting agents for precise gloss adjustment.

- AEROSIL® & AEROXIDE® – Rheology modifiers and scratch resistance for high-performance coatings.

Architectural & Industrial

- Dynasylan® – Silane adhesion promoters for long-term durability and corrosion resistance.

- SPHERILEX® – Silica for texture and matting effects in decorative and functional coatings.

- VPS – Specialty modifiers for enhanced flexibility and chemical resistance.

- VESTAGON® – Polyurethane crosslinkers for durable, light-stable and weather-resistant powder coating systems.

Recent Developments

- In October 2025, the PPG ENVIROCRON Extreme Protection Edge Plus power coating was launched by the PPG. This power coating is a patent-pending and one-coat innovation to enhance edge-protection technology.

- In July 2023, BASF SE entered a partnership with Zhejiang Guanghua Technology Co., Ltd. (KHUA), which states that BASF SE will supply KHUA with Neopentyl Glycol (NPG). KHUA manufactures polyester resins used for powder coatings. The partnership is expected to help meet the growing demand from China and other Asia Pacific countries.

- In May 2023, PPG Industries, Inc. announced an investment of USD 44 million in five powder coating manufacturing facilities in Latin America and the U.S. The project is in line with the company’s strategic initiative to increase powder coating production and strengthen its product portfolio to cater to growing demand.

Powder Coatings Market Top Key Companies:

- Akzo Nobel N.V. (Netherlands)

- PPG Industries, Inc. (U.S.)

- BASF SE (Germany)

- Jotun (Norway)s

- Axalta Coating Systems, LLC (U.S.)

- The Sherwin-Williams Company (U.S.)

- Asian Paints (India)

- Kansai Nerolac Paints Limited (India)

- TCI Powder (U.S.)

- Berger Paints India Limited (India)

Powder Coatings Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global Powder Coatings Market

By Resin

- Epoxy

- Polyester

- Epoxy-Polyester (Hybrid)

- Acrylic

- Polyurethane

- Others

By Application

- Consumer Goods

- Architectural

- Automotive

- General Industries

- Furniture

- Others

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5513

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics | TCM Blog

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/